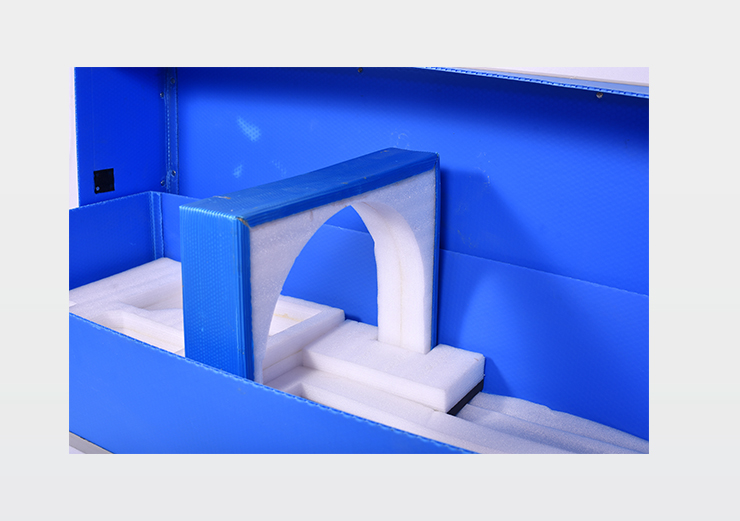

PP Box with Foam

Optipac Group Private LimitedPP boxes with foam inserts combine the durability of polypropylene (PP) corrugated plastic with the superior cushioning of foam, creating a robust packaging solution for delicate and high-value items. The PP box provides structural strength and resistance to moisture and chemicals, while the custom-fitted foam inserts offer exceptional shock absorption and vibration dampening. This combination ensures maximum protection during transit and storage, preventing damage from impacts and movement. PP boxes with foam inserts are widely used in industries such as electronics, aerospace, and medical equipment, where product integrity is paramount. Optipac Group Private Limited delivers these specialized packaging solutions, engineered to meet the most demanding protection requirements.

Benefits of PP Box with Foam

Superior Protection

Combines PP box durability with foam cushioning for maximum protection.

Shock Absorption

Foam inserts provide excellent cushioning against impacts and vibrations.

Customization

Foam inserts can be custom-designed to fit specific product shapes and sizes.

Moisture Resistance

PP box provides resistance to moisture, protecting contents in humid conditions.

Chemical Resistance

PP box is resistant to a wide range of chemicals, oils, and solvents.

Durable and Reusable

Both the PP box and foam inserts are durable and can be reused.

Recyclable Components

PP box is made from recyclable material, and some foam types are also recyclable.

Cost-Effective Protection

Provides a cost-effective solution for protecting high-value items.

Versatile Applications

Used in various industries, including electronics, aerospace, and medical.